Send us your project information and our Sales & Engineering team will be in touch with you the same day.

Request A Quote

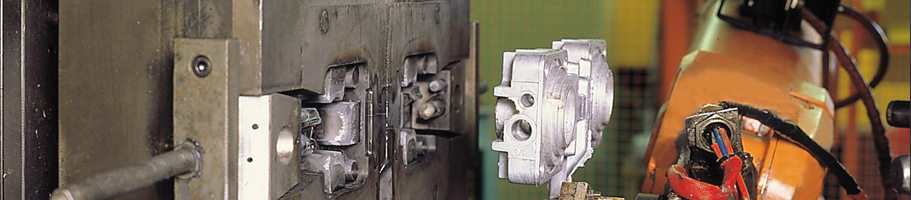

Aluminum Die Casting

Aluminum Die Casting Materials

- A380, A360, and A356

Aluminum Die Casting Design Criteria

- As cast tolerances as tight as +/- .005”, post machining available for tighter tolerance applications.

- Standard tolerance of +/- .010” for the first inch and +/-.002” each additional inch.

- Typical surface finish of Ra 63-125 micro-inch as cast, post machining available for higher quality finishes.

- Minimum draft = .5 degrees

- Minimum wall thickness = .030” (Thinner wall thickness possible with alternative processes)

Production Aluminum Die Casting

Hard tool or H-13 aluminum die cast tooling is an excellent process for higher quantity casting requirements. A larger upfront tooling investment yields a significant reduction in re-occurring casting costs. Production die castings have highly repeatable properties and tolerances.

Typical lead time:

- Hard Tooling = 4 weeks

- Samples = 1-2 weeks

- Production castings (Qty 10k) = 3-4 weeks

Tooling life expectancy:

- 500k shots

Prototype High Pressure Die Cast Soft Tooling

The term “Soft Tool” is used to describe an aluminum die casting tool made out of P-20 steel. The P-20 steel is softer than H-13 steel and thus yields aluminum die castings in less time with a decrease in tooling cost. This is attributed to the ability to run faster feed rates when CNC machining the tool. Typically a P-20 tool can yield 10,000-40,000 castings before showing any significant wear.

Typical Lead time:

- Soft Tooling = 2 weeks

- Samples = 1 week

- Production castings (Qty 100) = 3-5 days

Tooling life expectancy:

- 500k shots

What our customers say

“Without Spectron our project would not have been as successful as it was. They demonstrated the teamwork, knowledge, and ‘can-do’ attitude needed to pull off a difficult order”

Preferred Vendor For