Send us your project information and our Sales & Engineering team will be in touch with you the same day.

Request A Quote

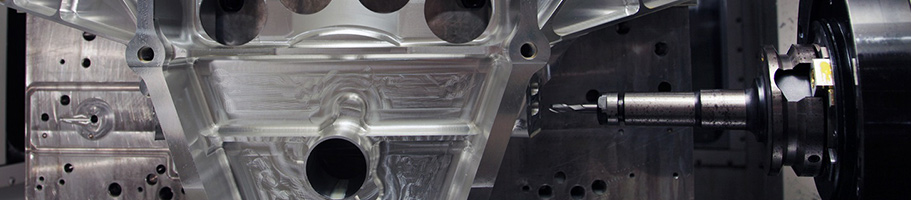

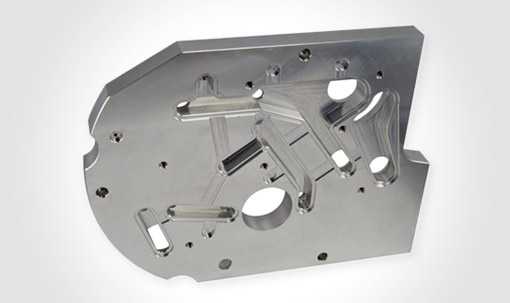

CNC Machining

CNC milling is among the most common forms of precision CNC machining. CNC milling is a cutting process in which a block or billet of material is milled by a computer-controlled tool which moves and rotates around the product as it is shaped. CNC milling is a common process that creates precise machined parts and components quickly and accurately. We operate using a variety of cutting tools to ensure exact specified shapes and dimensions for every component can be machined. Our capabilities include:

- Rapid lead times

- Prototype and production qtys (1-100,000)

- Multiple 3, 4, and 5 axis mills, combination lathes, and swiss turning centers

- Materials available include magnesium, aluminum, zinc, steel, copper, bronze, titanium, and a variety of plastics.

CNC Machine Shop Equipment List

Milling

- Haas VF-5 XT w/TRT-210 4th, 5th Axis Rotary Table

- Haas VF-3 Vertical Mill w/HRT-210 4th Axis

- Okuma LC 30 with 42” between centers

- Mori-Seiki CL203 * Mori-Seiki SL 603 Big Bore (11” Spindle Bore, Two Meter Bed)

- (2) Fadal VMC 15XT Machining Center, 16”x30” table

- Fadal VMC3016L Machining Center, 16”x30” table

- Fadal VMC4020 Machining Center, 20”x48” table with 4th Axis & Automatic Indexer

- Fadal VMC3016L Machining Center, 16”x30” table with 4th Axis & Automatic Indexer

- (2) Lagun vertical mill

- (2) BridgePort series 2 vertical mill

- (2) Bridgeport Mill with 42” tables/digital readout

Grinding and Lapping

- (3) Koa Ming manual grinders

- Cincinnati Monoset universal grinder

- Lapmaster lapping machine

- 6”x12” Boyer Shultz Surface Grinder

- (2) Surface Plate 24”x36”

See our Lathe Department for additional equipment.

What our customers say

“Spectron Manufacturing has been easy to deal with and always seems to go above and beyond to meet our needs. They have consistently been one of our top performing suppliers in terms of quality, value and on-time delivery.”

Preferred Vendor For